Modifying Soil Shear Strength Parameters Using Additives in Laboratory Condition

Marjan Sadrjamali1 * , Seyed Mojtaba Athar2 and Alireza Negahdar3

1

Department of Civil Engineering,

Mohaghegh Ardabili University,

Ardabil,

Iran

2

Department of Civil Engineering,

Sama Technical and Vocational training College,

Islamic Azad University,

Ardabil Branch, Ardabil,

Iran

3

Department of Civil Engineering,

Mohaghegh Ardabili University,

Ardabil,

Iran

Corresponding author Email: m.sadrjamali@yahoo.com

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.17

Mechanical and chemical processes and/or reinforcing materials are used in order to increase soil shear strength. Necessity for reinforcing and strengthening of soil in geotechnical and civil engineering projects requires use of new materials and reinforces. In recent years, although researchers have used new chemical compounds, however, nano-particles have not found their suitable situation. In this study, we have tried to increase soil shear strength parameters using different additives. Clay minerals are considered as problematic soils due to their engineering features. So, it is essential to reclaim them. In this research, clay with low plasticity property has been studied. Soil shear strength is an important factor for any analysis associated with stability including slope stability analysis. Slope stability analysis is used in earth dams and trenches. In this study, we have tried to increase soil shear strength parameters, i.e. cohesion coefficient (C) and internal friction angle (φ) using different additives. Direct shear test has been used for obtaining shear strength parameters as well as Mohr-Coulomb theory has been utilized for calculating of them. Although direct shear machine has its defects and its accuracy is low in comparison with tri-axial machine, however in this study it has been selected due to its simplicity and cheapness. Since this investigation aims to compare various additives and all tests have been done at same condition by direct shear machine, its deficiencies have been neglected. Additives used in present research include: Nano-silica in various percentage, Micro-silica, cement, lime (Cao) and these materials’ combination with together. The reason to choose Nano-silica is that it is a very active super-pozzolanic additive. This additive increases strength of sample significantly through chemical actions. Using silica in soil stabilization depends on type and size of silica particles so that the more finely the more continuous gradation, so property of being finer leads to decrease pores among particles and results to increase strength while light gradation has been achieved. Silica is one of the most popular materials which play a significant role in cohesion and filling. Results of experiments have shown significant effect of these additives in increase of soil shear strength parameters. The lime leads to modify behavioral features of fine-grained soils containing clay (properties such as swelling, shear strength, water absorption ability and plasticity properties) but it should not be in vicinity of sulphate ions.Since, in this condition, presence of lime not only doesn’t play an effective role but also it results to decrease in strength as well as increase in swelling. With regard to this reason, Calcium sulfate (gypsum) was added to soils containing lime in order to study swelling of soils stabilized with lime and nano-silica. Nano-silica increases Soil shear strength parameters while it is efficient in increasing of soil swelling, too.

Copy the following to cite this article:

Sadrjamali M, Athar S. M, Negahdar A. Modifying Soil Shear Strength Parameters Using Additives in Laboratory Condition. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.17

Copy the following to cite this URL:

Sadrjamali M, Athar S. M, Negahdar A. Modifying Soil Shear Strength Parameters Using Additives in Laboratory Condition. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=10929

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2014-11-31 |

|---|---|

| Accepted: | 2014-11-04 |

Introduction

The natural soil existed in site of structures is not always suitable for supporting of that in a properly manner. Clay minerals can cause different problems in various projects due to their high water absorption and retention and being fine- grained. In other words, most of problematic soils, except liquefiable soils, have been constituted from clay minerals, so it is necessary to reclaim them. In this study, clay soil with low plasticity index (CL) has been investigated. Use of additives is one of the methods for modifying soils. Common additives for stabilizing goals includes: cement, lime, calcium chloride, fly ash cement and etc (Daniels et al., 2004). By adding these additives, researchers could increase strength and durability of soils as well as deformation and permeability of them have been decreased. Use of Nono-particles as a new additive is not common. Nono-particles have particular characteristics, so use of this new additive leads to considerable changes in soil structure. Nono-particles are more active than soil particles so that it can enter in actions solely due to its high special area (Guoping, 2000). In this study, Nano-silica in various percentages has been used to stabilize the soil. in recent years, many studies have been done on adding Nano-silica to cement (Hui et al., 2003). In present paper, Nano-silica has been added to the soil solely as well as in combination with other additives such as cement, lime and micro-silica. Using silica in soil stabilization depends on type and size of silica particles so that the more finer (to Nano dimension) the more continuous gradation, so property of being finer leads to decrease pores among particles and results to increase strength while light gradation has been achieved. Miwa and Ion Cora (1992) have used Nono-particles to increase soil compressive strength (Yonekura et al., 1993). Nol investigated effect of Nano-silica on increase of soil strength against to penetration (Nol et al., 1992). in 2005, Nano-silica has been used in order to increase cohesion as well as decrees in viscosity and it is found that amount of cohesion has a relation with percentage of Nano-silica (Gallagher et al., 2005). Patricia have investigated effect of Nano-particles on sands with high viscosity (Gallagher et al., 2007). Zhang claimed that use of Nano-particles leads to increase in Atterberg limits (Zhang et al., 2004). Strengthening of soil with lime was common since ancient times and in America, modifying soil with hydrated lime was prevailed since 1945. Croft found that adding lime to soils leads to decrease in swelling, liquid limit, plasticity index and maximum dry specific gravity. It also results to increase in optimum moisture content, shrinkage limit and strength (Croft et al., 1996). In different studies (Bell) optimum percentage for lime has been proposed 1-3 percent respect to dry soil weight. More than this value has not significant effect on plasticity characteristics but it will increase soil strength. While other studies suggested 2-8 percent for lime in order to modify soil features (Bassma et al., 1991),. The lime leads to modify behavioral features of fine-grained soils containing clay (properties such as swelling, water absorption ability and plasticity). The lime should not be in vicinity of sulphate ions since, in this condition, presence of lime not only doesn’t play an effective role but also it leads to decrease in strength while increase in swelling. This phenomenon is occurred due to chemical actions among clay minerals, lime and sulphate, that leads to formation of ettringite and thaumasite minerals. These minerals are swelled due to water absorption. In recent years, unsuccessful experiences have been observed in relation to stabilizing soils with lime in Europe [Mitchell et al., 1986 & Ferris et al., 1991)]. Next studies by them indicate presence of soluble sulphates - especially calcium sulphates- and ettringite and thaumasite minerals within soil of interested regions. Formation of these harmful minerals is due to chemical actions among clays, limes and sulphates. So in this study, effect of adding Nano-silica in various percentages (1%, 2%, 3%, 4% and 5%) into samples containing gypsum and lime was studied by performing free swelling test. Accurately determining of shear strength parameters in fine-grained soils has its special difficulties. One of the most important such problem is to provide undisturbed samples which have appropriate quality in order to conduct soil shear strength tests. Direct shear test has been used for obtaining shear strength parameters. Although direct shear machine has its defects and its accuracy is low in comparison with tri-axial machine, however it has been selected due to its simplicity and cheapness. Since this investigation aims to compare various additives and all tests have been done at same condition by direct shear machine, its deficiencies have been neglected.

Materials

Soil

The soil used in this study is CL based on unified classification. Liquid limit (LL) and plasticity limit (PL) for this soil have been determined based on ASTM D4318 standard. Table.1 shows physical characteristics of this soil.

Table1: Physical Characteristics of Soil

|

Specific Density (Gs) |

2.56 |

|

Liquid Limit (%) |

39 |

|

Plasticity Limit (%) |

25 |

|

Plasticity Index (%) |

14 |

|

Distribution of Soil Sizes (%) |

|

|

Sand |

40 |

|

Silt |

14 |

|

Clay |

46 |

|

Compaction characteristics |

|

|

Optimum Moisture Content |

14.10 |

|

Maximum Dry Specific Gravity |

19.80 |

|

Soil Classification in Unified System |

CL |

Nano-Silica

Nano-silica used in this study was as white powder that provided by Iranian Nano-silica Pioneers Company (Sani). Physical characteristics of Nano-silica have been shown in Table.2. These features are based on information provided by Sani CO.

Table2: Physical Characteristics of Nano-Silica

|

Density |

2.40 |

|

Size of Particles (nm) |

20-30 |

|

Special Area (m2/gr) |

180-600 |

|

Purity (%) |

>99 |

Cement

The cement used in present study was Portland cement that produced at Ardabil cement factory.

Micro-silica

Micro-silica used in this study, has been provided by Sina Powder Jam Company. Its skilled producing is based on ASTM C1240- EN13263. Table.3 shows physical characteristics of Micro- silica.

Table3: Physical Characteristics of Micro-Silica

|

Density |

2.20 |

|

Volumetric Density |

600 |

|

Apparent Density |

0.60 |

|

Pozzolanic Activity Coefficient (7-days) |

114-117 |

Lime

The lime used in this study is hydrated industrial lime called calcium hydroxide and there is in 10kg packages. Its color is white and its density and specific gravity are 2.35 and 5.5KN/m3, respectively.

Calcium Sulfate (gypsum)

Gypsum is common sulphate in natural soils. In this study, hydrate calcium sulfate (CaSO4.H2O) - that called gypsum industrially and provided in 20 Kg packages- has been used.

Method of Testing

Required soils for providing samples should be so sufficient that we can obtain all our similar samples. In stabilization process, the soil become disturbed, so considering stabilization methods, samples are reconstituted ones. The sample is reconstituted through shear compressing or compacting layer by layer so that final accumulated weight of reconstituted sample in mold has a definite volume. In group1 experiments, Nano-silica powder as a solution in aquaria in 2, 3, 4, 5, 7 percents respect to dry soil weight was distributed throughout the sample smoothly, then the soil- silica admixture was cast in prepared molds and afterward was compacted by a 4 kg standard hammer in each layer (with regard to optimum moisture content and maximum dry specific gravity for each soil). Since Nano-silica and Micro-silica are fine-grained particles and their amount is low in comparison with sample volume, their effects on moisture content and maximum dry specific gravity were ignored. In group2 experiments, the sample was stabilized with cement, then Nano-silica and Micro-silica in various percentages were added to soil stabilized with cement, afterward their effects on soil shear strength parameters were investigated. Based on Michel and Freytag work, volumetric amount of cement for stabilizing of CL soil is 12 percent respect to weight of dry sample. At first, 12 percent cement (respect to sample dry weight) was distributed throughout of the sample, then the soil mixed with cement was cast layer by layer in prepared molds and afterward each layer was compacted using a standard hammer. The molds containing samples were kept at 25 °C and optimum moisture content of the soil for 20 days. For preparing other samples, the percent of cement was decreased up to 6% and Nano-silica in 4, 3 and 2 percent (respect to cement weight) was added to soil and then micro-silica in 6, 5 and 4 percent was added to soil in addition to 6% cement. This group tests aim to give comparison between Nano-silica and Micro-silica. When Nano-silica is added to soil, use of cement is decreased up to 50% while better results have been achieved. In group3 experiments, lime was used as a stabilizer additive and Nano-silica was functioned as an amplifier additive. The lime as swelling, water absorption ability and plasticity). As mentioned previously, the lime should not be in vicinity of sulphate ions since, in this condition, presence of lime not only doesn’t play an effective role but also it leads to decrease in strength while increase in swelling. This phenomenon is occurred due to chemical actions among clay minerals, lime and sulphate, that leads to formation of ettringite and thaumasite minerals. These minerals are swelled due to water absorption. In tests of this group, 5% (respect to weight of dry sample) gypsum –common sulphates in soils- has been added to samples. Since lime is swelled at vicinity of soil containing sulphate, so amount of swelling was checked through free swelling test and effect of adding Nano-silica into samples containing gypsum and lime was studied. Although stabilization of soil with Nano-silica and lime is very effective, however its influence in adjacent with sulphates should be checked in order to prevent subsequent problems.

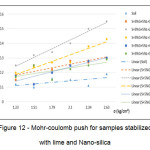

All experiments have been done through slow and saturated method under vertical stresses equal to 1.23, 1.51, 1.79, 2.1, 2.34 and 2.63 kg/cm2. Tests were done in consolidated drained condition at 0.05 mm/min rate, then internal friction angle and cohesion coefficient soil shear strength parameters were obtained by drawing Mohr-coulomb push.

Results of Experiments

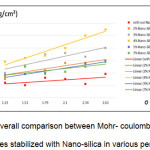

More than 150 samples were tested. Finally 114 tests were accepted among various samples. Mohr-coulomb push has been drawn for various states, as have been shown in following figures. In these figures, S, N, C, M, L and G refer to soil, Nano-silica, cement, Micro-silica, lime and gypsum, respectively.

|

|

|

|

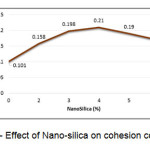

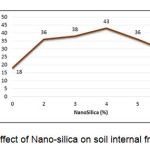

In this group tests, adding 4 percent Nano-silica to the sample has the most effective influence in soil shear strength parameters. So, with regard to results of conducted tests, optimum value for stabilizing of soil using Nano- silica equals to 4%. Nano-silica has high specific area. Also this additive is an amorphous material so it is very active and was high ability to participate in chemical action. Nano-silica particles have powder state. If some water be added to this additive and to be allowed to lose its water gradually, this material changes its state to soild state with very high strength that is, it has cementation property due to high surface charge and intrest to do actions with together when water is added. This subject has been proven by researchers through SEM photography. In stabilizing process, if some pozzolan is used accomplish with Nano-silica, pozzolanic action will be started when same water is added to soil. In figures 3 and 4, effect of Nano-silica in various percents on soil shear strength parameters has been shown schematically.

|

|

|

|

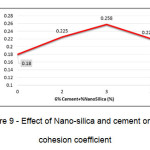

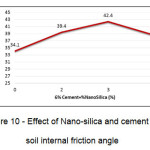

In figures 5-10, results of tests conducted on samples containing various percents of Nano-silica, Micro silica and cement have been shown. It can be observed in figure 5 that when 5 percent Micro-silica is added to soil, internal friction angle is one degree more than when Micro-silica percent is 4%, while in latter case cohesion coefficient is 15% more than former state. So optimum value of Micro-silica that has been added to soil - 6percent cement admixture is 4 percent. In optimum state, internal fiction angle is 12% and 112% more than states which 12% cement or no additive have been added to soil, respectively. These increases for cohesion coefficient at optimum state are 6% and 88%, respectively. Samples stabilized with 6% cement and 4% Micro-silica have maximum shear stress (under constant vertical stress) in comparison with other values.

|

|

|

|

|

Fig. 7: Effect of Micro-silica and cement on soil internal friction angle Click here to View figure |

It can be seen from figure 8 that samples stabilized with 6% cement and 2% Nano-silica can withstand higher shear stresses, particularly under higher constant vertical stress. In this group’s tests, it can be observed that optimum value of Nano-silica for stabilization of soil-6% cement admixture is 2 percent. In optimum state, internal friction of sample is 135%, 24% and 11% more than in comparison with samples without any additive, samples stabilized with 12% cement and samples stabilized with cement and Micro-silica, respectively. Also, this increase in cohesion coefficient at optimum state equals to 155%, 43% and 36%, respectively.

|

|

|

|

|

Fig. 10: Effect of Nano-silica and cement on soil internal friction angle Click here to View figure |

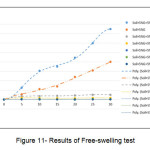

With regard to results of experiments, it can be said that a comparison has been done between Nano-silica and Micro silica features by adding them to soil-cement admixture. There are many differences between these two additives. Micro-silica is a silic product with 0.1-1mm in diameter. Although Micro-silica plays an effective role in increasing soil shear strength, however it lacks features of Nano soil-silica. Micro-silica cannot be used lonely in order to stabilize the soil. In other words, it has to be utilized accomplish with other additive as an activator starting pozolanic actions. Concerning results of experiments, in soils stabilized with Nano-silica and cement, cohesion coefficient and internal fiction angle are higher than soils stabilized with Micro-silica and cement. In other words, Nano-silica in low percent leads to better results in comparison with Micro-silica in high percent. Last group experiments deal with samples containing 5% gypsum, 5% lime and various percent of Nano-silica (1, 2, 3, 4 and 5). Although lime modifies behavioral properties of fine-grained soils containing clay (properties such as swelling, shear strength, water absorption and plasticity characteristics), however is should not be in adjacent to sulphate ions because in this condition, presence of lime not only isn’t effective but also it leads to increase in swelling as well as decrease in shear strength. As lime in soils containing sulphate results to aggravate swelling, hence value of swelling in samples was checked through conducting free-swelling test and then effect of adding Nano-silica into sample containing gypsum and lime was investigated. Since samples for doing free-swelling test are prepared at maximum dry specific gravity, initially it was required that standard compaction test to be done based on ASTM D698 standard. Results of compaction test have been shown in Tables.4 and 5.

Table4: Optimum moisture content obtained from compaction test

|

optimum moisture content |

samples |

|

19.50 |

soil+5% lime+5% gypsum |

|

19.90 |

soil+5% lime+5% gypsum +1% Nano-silica |

|

20.1 |

soil+5% lime+5% gypsum +2% Nano-silica |

|

20.90 |

soil+5% lime+5% gypsum +3% Nano-silica |

|

21.30 |

soil+5% lime+5% gypsum +4% Nano-silica |

|

22.10 |

soil+5% lime+5% gypsum+5% Nano-silica |

Table5: Maximum dry specific gravity obtained from compaction test

|

maximum dry specific gravity |

samples |

|

16.50 |

soil+5% lime+5% gypsum |

|

16.10 |

soil+5% lime+5% gypsum +1% Nano-silica |

|

15.90 |

soil+5% lime+5% gypsum +2% Nano-silica |

|

15.50 |

soil+5% lime+5% gypsum +3% Nano-silica |

|

15.20 |

soil+5% lime+5% gypsum +4% Nano-silica |

|

14.90 |

soil+5% lime+5% gypsum+5% Nano-silica |

In consolidation machine, sample is laterally limited; hence change in sample height implies change in volume. In this test, the samples have been prepared based on maximum dry specific gravity and they were got their required water because of saturation. In these samples 5% lime, 5% gypsum accomplish with Nano-silica in 0, 1, 2, 3, 4, 5 percent were used. Procedure of process was as follows: At first, required amounts of each one were mixed with together and then required water was added based on optimum moisture content achieved from compaction test. These admixtures were left freely to permit initial action to be occurred among them. And finally a homogenous mixture is acquired to preparing samples in consolidation machine. Results of free- swelling test in consolidation machine have been shown in figure11.

|

|

Concerning figure.11, it can be observed that swelling amount of soil-lime-gypsum admixture has been reduced significantly. Maximum swelling was seen in sample without Nano-silica. In fact, we can say that, swelling of soil- lime gypsum admixture is more times more than swelling of soil-gypsum admixture. Among samples containing Nano-silica, the highest swelling is associated with sample with 1% Nano-silica. Also, the lowest swelling corresponded to sample containing 5% Nano-silica. Note that samples containing 3.4 and 5% Nano-silica have approximately same swelling value and there is slight difference among them. In other words, swelling of these samples is very near to zero. Therefore, considering economic condition, optimum value for Nano-silica is 3% respect to dry weight of sample. In figure 12, results of direct shear test on samples containing lime, gypsum and Nano-silica in various percents have been shown.

|

|

With refer to figure12, optimum value of Nano-silica for stabilizing of soil-5% lime-5% gypsum admixture equals to 2% i.e. in this state, values of soil shear strength parameters are in the highest amount. However, considering results of free-swelling test in which optimum value for Nano-silica is 3%, and since discrepancy of internal friction angle and cohesion coefficient between samples stabilized with 2 and 3 percent Nano-silica is slight, then 3 percent Nano- silica is selected for stabilizing of soil- 5% gypsum--5% lime admixture. It can be observed that using Nano-silica can solve swelling problems of soils stabilized with lime exposed to sulphate ions effectively. Also concerning results of direct shear test, soil shear strength parameters have been increased considerably.

Discussion

As it is clear from experiments’ results, when percentage of Nano-silica increased soil shear strength parameters have increased primarily, then they have decreased. This reduction can be due to reasons as following: Since Nano-silica has high special area, so it cannot be distributed homogeneously in soil, hence physical superficial actions will be occurred among Nano-silica particles leads to formation of weakly and unstable clogs by Nano-silica particles. Also, if Nano-silica is used with other additives such as cement and lime, increasing Nano-silica leads not well actions to be done by cement and lime. In other words, value of compacted gel is more than produced crystals by additives which results to decreasing of strength when Nano-silica percent is increasing.

If only Nano-silica is used to modify soil shear strength parameters, the optimum value is 4%. In this state, internal friction angle and cohesion coefficient of soil stabilized with Nano-silica have been increased 138% and 107% in comparison with samples without any additive, respectively.

If Nano-silica is used accomplish with other additives, optimum amount of Nano-silica added to soil-cement mixture is 2% (6% respects to cement weight). Also, optimum value of Micro-silica is 5% (6% respect to cement weight).

Increase in strength due to adding 2% Nano-silica into soil- cement mixture is more than adding 5% Micro-silica to that. In this state, use of low-percent Nano-silica has better performance respect to using high- percent Micro-silica.

Whit regard to conducted studies, adding Nano-silica into soil has deceased swelling of problematic soils containing clay and gypsum significantly. It should be noted that maximum swelling has been occurred in samples without Nano-silica additives. Also swelling of soil-lime-gypsum admixture is very more than swelling of soil-gypsum admixture. In this state, considering economic condition, optimum value of Nano-silica is chosen equal 3% (respect to sample’s dry weight).

To achieve soil shear strength parameters, optimum value of Nano-silica for stabilizing of soil- 5% lime- 5% gypsum admixture is 2% based on direct shear test.

References

- Bassma, A.A.; Tuncer, E.R.; Effect of lime on volume change and compressibility of expansive clays. Transportation Research Board, Washington DC, TRR NO, pp54-61, (1991).

- Bell, FG. Lime Stabilization of clay minerals and soils. Engineering Geology, pp223-237.

- Croft, JB. The influence of soil mineralogical composition on cement stabilization geotechnique. Vol 17, London, England, (1996).

- Daniels, J. L; Inyang, H. L; Contaminant barrier material textural response to interaction with aqueous polymers. Journal of Material and Civil Engineering, 16, 365-275 (2004).

- Ferris, G. A.; Eades, J. L.; Graves, R. E.; and Maclellan, G. H.; Improved characteristics in sulfate soils treated with barium compounds before lime stabilization, Transportation Research Record, (1991).

- Gallagher, P.M; Conlee, C.T; Rollins, K. M; Full-Scale Field testing of colloidal Silica Grouting for Mitigation of Liquefaction Risk. ASCE-1090-0241, 133:2-186, (2007).

- Gallagher, P.M. Lin, Y. Column Testing to determine Colloid Silica Transport Mechanisms. Sessions of the Geo-Frontiers Congress, (2005).

- Guoping, Z. Nanoparticles and their Influence on engineering properties of soils (Geo-Institude, 2000)

- Hui, L; Hui-gang, X; Jie, Y; Ou Jinping, O; Microstructure of cement mortar with nano particles. Composite particles, Composites Part B: Engineering, (2003).

- Mitchell, J.K., Practical problems from surprising soil behavior, Geotechnical Engineering, ASCE, (1986).

- Noll, M. R. Baetlett, C. Dochat, T.M. In situ Permiability Reduction and Chemical Fixation using colloidal silica. National Outdoor Action Conference, Las Vegas, (1992).

- Yonekura, B. Miwa, M. (1993), Fundamental Properties of Sodium Silicate Based Grout. Geotechnical Conference, Singapore, (1993).

- Zhang, G.; Germaine, J. T.; Whittle, A.J.; and Ladd, C.; Index properties of highly weathered old alluvium. Geotechnique 54, No.7, 441-451, (2004).